Roller Bearing, Retainer, Adapter, and Fastener

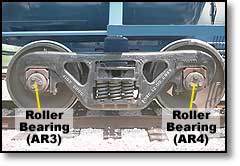

Roller Bearing, Retainer, Adapter, and FastenerAll rail cars including tank cars must be equipped with AAR approved roller bearings. Roller bearing components include:

- the housing

- front and rear seals

- rear retainer ring

- rotating or non-rotating end cap

- cap screws

- cap screw locking plate

- Necessary accessories including: the roller bearing adapter, side frame upper wear plate, roller bearing retainer, and the roller bearing retainer fastener.

If you are able to inspect the tank car immediately after it has been spotted, check for signs of overheating (e.g., metal discoloration) or heat coming from the bearing. Rub a 200 degree Fahrenheit temple (heat) stick against the roller bearing adapter only, as shown. If the heat stick melts, the roller bearing is defective.

If you are able to inspect the tank car immediately after it has been spotted, check for signs of overheating (e.g., metal discoloration) or heat coming from the bearing. Rub a 200 degree Fahrenheit temple (heat) stick against the roller bearing adapter only, as shown. If the heat stick melts, the roller bearing is defective.Most welding shops will have these temperature sticks. Contact a welding supplier if temple sticks are unavailable at your site.

Roller Bearing Adapter

Roller Bearing AdapterThe roller bearing adapter allows the side frame and roller bearing to mate together. A correctly sized adapter assures the weight of the tank car will rest evenly along the entire length of this and every roller bearing on the truck. Uneven weight distribution can cause excessive wear and overheating of the roller bearing, adapter and other related parts.

Adapters must be checked for cracks, wrong size, excessive wear and signs of overheating. Do not load a tank car that has any defective roller bearings.

If the adapter is worn on the crown of the adapter to the extent that the frame bears on the relief portion of the adapter, then the adapter is defective. A mobile tank car repair crew will be able to repair the roller bearing adapter in place.

Roller Bearing Retainer ( Frame Key ) and Fasteners

Roller Bearing Retainer ( Frame Key ) and FastenersFrame keys attach to the bottom of the side frame pedestal, as shown. Their function is to hold the wheel set and trucks together in a derailment. If present, check to make sure they are secure. Missing frame keys do not have to be replaced.

Frame key fasteners are 1/2" steel bolts and a locking nut.

Defective Roller Bearing Components

- External parts visibly cracked, broken or bent.

- Wrong size bearing, not standard to the tank car.

- Loose backing ring. A backing ring that can be moved by hand is considered loose.

- A loose, cocked or damaged seal.

- If the seal can be moved by hand, using a suitable probe, it is considered loose.

- If the seal is cocked out of position.

- One or more visibly loose or missing cap screws.

- Roller bearing showing signs of overheating.

- Signs of flood damage.

- Knowledge of the truck assembly being involved in a minor derailment.

- Roller bearings must be removed, inspected and replaced if the tank car was traveling over 10 miles an hour and moved along the ground more than 200 feet (as per AAR Rule 36).