Bottom Outlets (Unloading Systems)

Bottom Outlets (Unloading Systems)Bottom outlets on hopper cars come in several types and are either bolted or welded onto the hopper car. Types include a gravity pneumatic, sparger, fluidized butterfly, fluidized pneumatic, adjustable pneumatic, and gravity sliding type discharge.

Hopper cars bottom outlets are of steel, stainless steel, or aluminum construction.

All bottom outlets must be leak free, be equipped with attached bottom outlet caps. All outlets must operate properly, be compatible with the products they carry and meet minimum clearance requirements set by the DOT.

Only properly trained personnel, observing all company standard operating procedures (SOPs) should load and/or unload a hopper car. These operators are responsible for all fittings on the top and bottom of the hopper car.

|

|

If hopper car unloading is discontinued for any reason or unloading is complete, all hatch covers should be closed and be wrench tight, all unloading connections to process disconnected and end closures applied wrench tight.

All bottom outlet caps must be properly fastened and equipped with a chain or other type of securement.

Open hatches on hopper cars loading or unloading flammable materials must be protected against the entrance of sparks or other sources of ignition. This can be accomplished with flame arrestor equipped temporary covers.

Care must be taken to prevent foreign substances from accidentally falling into the hopper. Any spillage that occurs should also be properly cleaned up.

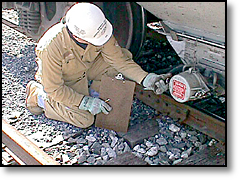

Follow these rules before removing any bottom outlet cap:

1. Check to make sure bottom outlet valve is closed.

2. Wear all required personal protective gear.

3. Place a drip pan under the bottom outlet discharge port.

4. Check to make sure the outlet valve is closed.

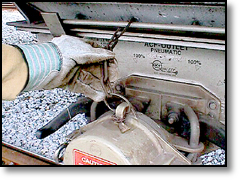

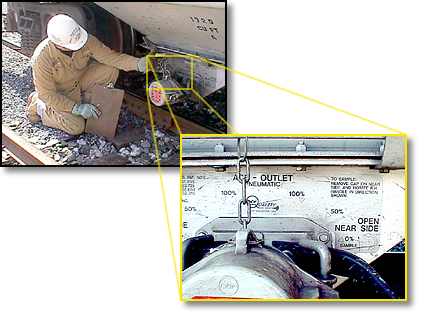

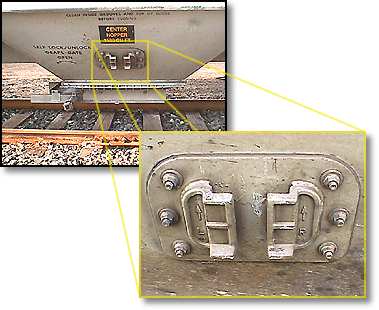

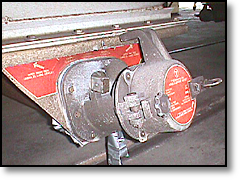

5. Use a suitable tool to remove outlet cap and slowly loosen bottom outlet control valve. Many outlet valves have instruction decals on them as shown in the picture below.

A good practice is to seal the bottom outlet after securing it properly. The seal should be installed properly and the number of the seal recorded on your inspection sheet.

Bottom outlet caps must be attached by chain or wire rope and be of an approved design.

All outlet valves must be properly secured and equipped with a chain or other type of securement.

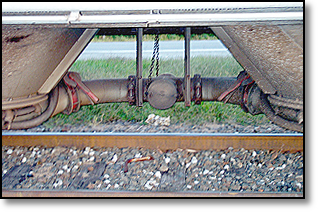

Hopper car bottom outlets, mounted valves, caps and other fixtures must be a minimum of 2-3/4" above the rail.

The bottom gravity pneumatic outlet valve is designed to provide controlled, unobstructed gravity discharge or pneumatic flow into a vacuum conveying system.

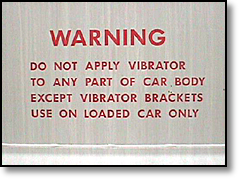

Vibrator brackets are optional. These outlets are generally used for bulk commodity ladings such as salt, lime and graphite. It is extremely important to make sure the bottom doors are closed and properly secured as during shipment they can be torn off. The valve must be one approved by the AAR.

Vibrator brackets are supplied on some hopper cars outlet chutes. When the vibrator is attached it helps move heavy, coarse products through the bottom outlet.

Hearing protection should be worn when working around hopper cars using vibrators, since the local noise level is extremely high.

Adjustable pneumatic outlets provide controlled pneumatic flow into vacuum unloading systems. They are completely sanitary and easy to clean. They come in several styles with additional features such as easy and complete clean-out without disassembly, an improved locking device for end caps, and easy operation.

Both the cap gasket and the mounting flange gasket must be sized properly and made of a material compatible with the product in the hopper car. Gasket material comes in white neoprene, black neoprene, and white PVC for pneumatic bottom outlets. This information should be included in your packaging standard.

Some cargo can be shipped in a dry state, but can be offloaded (and later used) in a wet state. Sparger outlets make it economical to ship such cargo by supplying a system to accomplish this type of offloading. A sparger hopper car will have a sparger loop which promotes full and easy control when offloading in this manner.

.jpg)

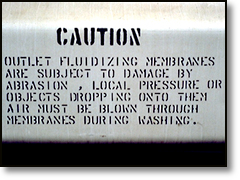

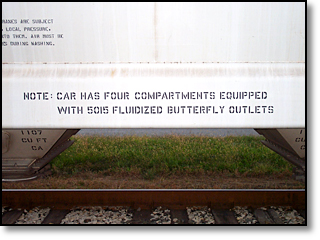

Fluidized Butterfly Outlet

Fluidized butterfly outlets provide sanitary gravity discharge for ladings requiring air assist for unloading. Care must be taken to prevent damage to the fluidizing membranes when applying pressure, or objects dropping onto them. Air must be blown through membranes during washing.

Both the membrane mounting and the mounting flange gasket must be sized properly and made of a material compatible with the product in the hopper car. For products in food-grade service, all gaskets and "O" rings must be FDA approved. This information should be included in your packaging standard.

Fluidized butterfly outlets provide sanitary gravity discharge for ladings requiring air assist for unloading. Care must be taken to prevent damage to the fluidizing membranes when applying pressure, or objects dropping onto them. Air must be blown through membranes during washing.

Both the membrane mounting and the mounting flange gasket must be sized properly and made of a material compatible with the product in the hopper car. For products in food-grade service, all gaskets and "O" rings must be FDA approved. This information should be included in your packaging standard.

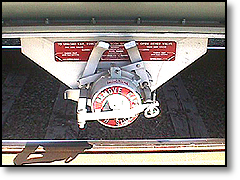

Pressure Hopper Car-Bottom Operating System

.jpg)

|

|

|

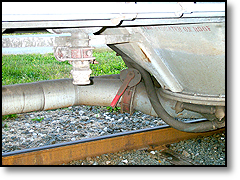

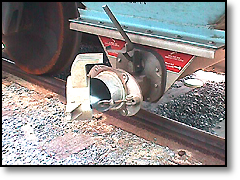

A thorough inspection of this bottom outlet would have picked up the missing bolts. But that wasn’t the case when this hopper car was loaded and shipped. The load spilled in transit. |

|

This outlet valve was missing when it returned from a customer. This could have been avoided if the outlet and caps had been properly secured. |

|

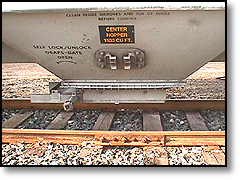

Bottom outlet caps must be closed and secured before the hopper car can be shipped. |

|

By leaving the bottom outlet caps off and outlet valve open, moisture and dirt can enter the hopper compartment. |

|

A derailment caused this damage. |

|

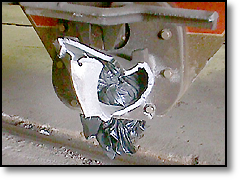

This damage was caused by using a sledge hammer to open the valve. |

.jpg) |

We cannot stress enough the importance of making sure that the hopper car or vessel you are offloading does not create a vacuum. This is what can happen when a vacuum is created due to improper venting. |